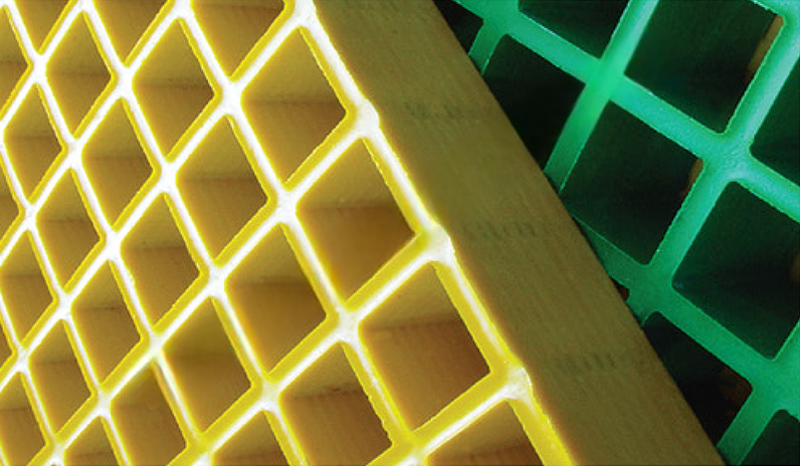

High-performance FRP Molded Gratings

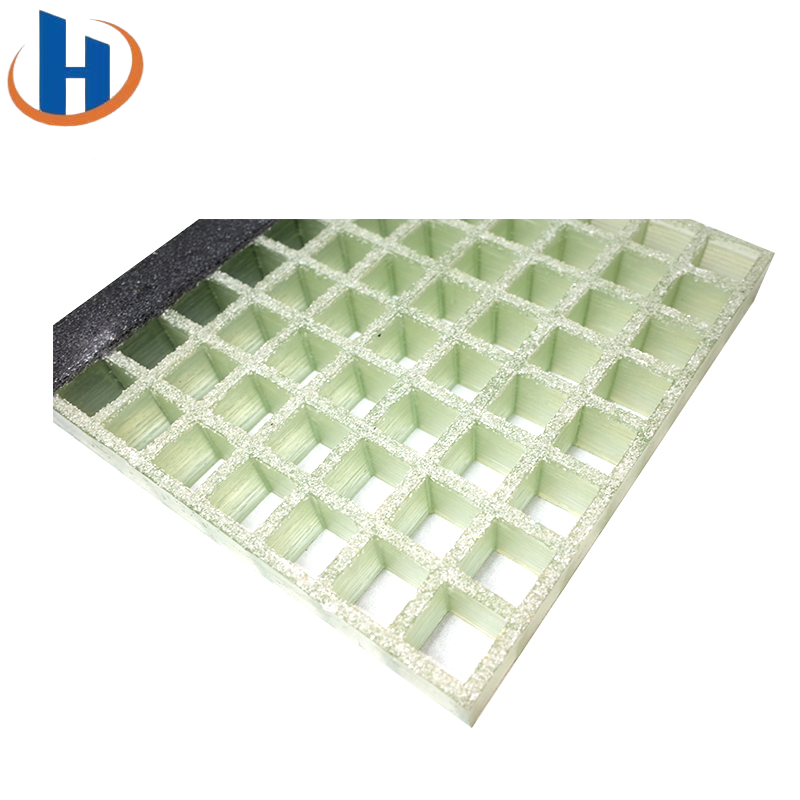

Our FRP molded grating, also known as fiberglass reinforced plastic molded grating, is a durable plank-shaped material made from a blend of unsaturated resins and reinforced with fiberglass roving. This molded fiberglass construction makes it exceptionally strong and versatile, ideal for a wide range of applications, including platforms, stair treads, ramps, catwalks, and trench covers. Our FRP molded gratings deliver exceptional performance and value, whether you require durable plastic grating panels or lightweight plastic grating sheets.

Features

- Corrosion Resistant: Thrives in environments prone to chemical exposure, resisting corrosion from submersion, spills, and gases.

- Fire Resistant: Meets ASTM E-84 Class 1 standards for fire safety, ensuring protection and compliance.

- UV Resistant: Maintains structural integrity and appearance, even with prolonged sun exposure.

- Lightweight: Simplifies installation without the need for heavy lifting equipment, reducing labor costs.

- Cost-Efficient: Delivers long service life and minimal maintenance, maximizing return on investment.

- Highly Durable: Offers robust load-bearing capacity, ensuring reliable performance in demanding applications.

- Non-Sparking: Safe for use in environments with combustible gases, preventing sparking upon impact with metallic objects.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

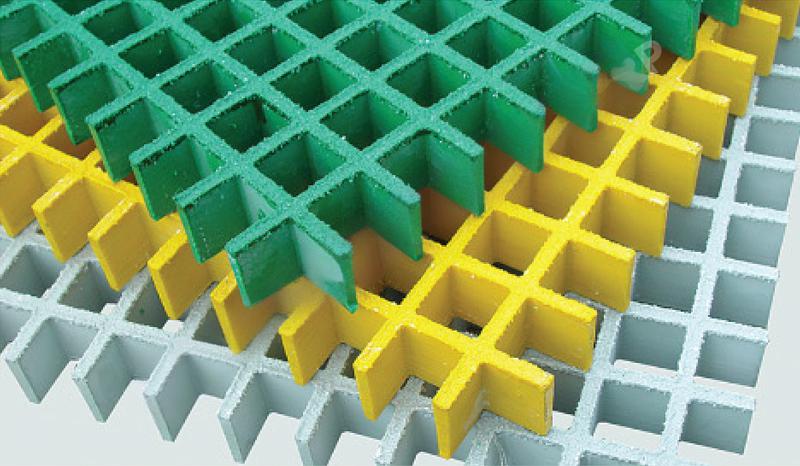

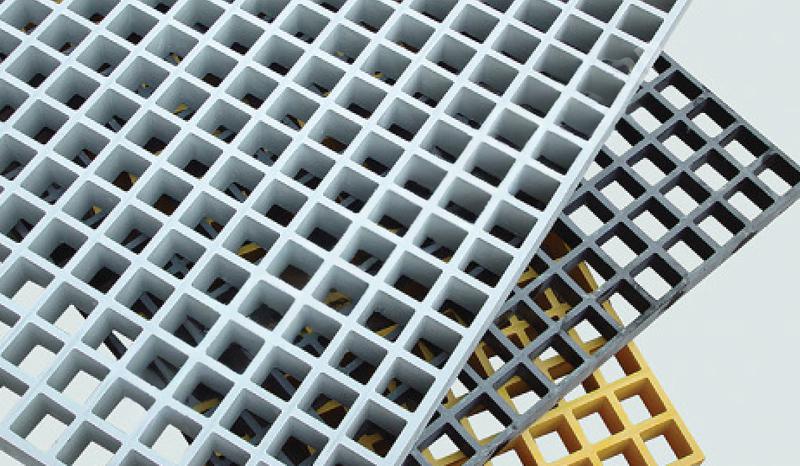

Mesh Table

| Mesh Shape | Thickness (mm) | Mesh Size (mm) | Panel dimension (mm) | Open area (%) | Weight (kg/m²) |

|---|---|---|---|---|---|

| Normal Square Mesh | 13 | 38*38 | 1220*4000, 1220*3660, 1220*2440, 915*3050 | 78 | 6 |

| 25 | 38*38 | 1220*4000, 1220*3660, 1220*2440, 915*3050 | 68 | 12.3 | |

| 30 | 38*38 | 1220*4000, 1220*3660, 1220*2440, 915*3050 | 68 | 14.6 | |

| 38 | 38*38 | 1220*4000, 1220*3660, 1220*2440, 915*3050, 1524*3050, 1524*4000 | 68 | 19.5 | |

| 25 | 40*40 | 12474047, 1007*3007 | 67 | 12 | |

| 30 | 40*40 | 1247*4047 | 67 | 14.5 | |

| 40 | 40*40 | 12474047, 1007*3007 | 67 | 19.2 | |

| 13 | 50*50 | 1220*3660, 1220*2440, 915*3050 | 82 | 5.8 | |

| 50 | 50*50 | 1524400, 1220*3660, 1220*2440, 915*3050 | 78 | 23.7 | |

| 25 | 25*100 | 1220*3660 | 67 | 13.9 | |

| Mini Mesh | 25 | 19*19/38*38 | 1220*4000, 1220*3660, 1220*2440, 915*3050 | 40 | 16.8 |

| 38 | 19*19/38*38 | 1524400, 1220*3660, 1220*2440, 915*3050 | 40 | 23.5 | |

| 50 | 25*25/50*50 | 1524*4000 | 55 | 28.5 | |

| Heavy Duty | 50 | 38*38 | 1220*4000, 1220*3660, 1220*2440, 915*3050 | 56 | 42 |

| 60 | 38*38 | 1220*4000, 1220*3660, 1220*2440, 915*3050 | 54 | 50.4 | |

| 25 | 25*100 | 1220*3660 | 52 | 19.5 |

Everything You Think About

Resin Matrix

| Type | Resin Matrix | Anti-Corrosion Class | Fire Retardancy | Applications |

|---|---|---|---|---|

| VCF | Vinylester | Chemical grade | Fire proof, OI>28 | Acid, alkali solvents and other corrosive environments |

| IIF | Iso | Industrial grade | Fire proof, OI>28 | Medium degree of acid and alkali corrosive environment |

| IFF | Iso-food grade | Industrial food grade | Fire proof, OI>28 | Meat products and other food processing plants |

| OAF | Ortho | Construction grade | Fire proof, OI>28 | General acid and alkali corrosive environment |

| OAN | Ortho | Construction grade | No fire retardancy | General acid and alkali corrosive environment and no flame retardant requirements |

| PIN | Phenolic | Industrial grade | High Fire proof, OI>80 | High fire resistance, low smoke requirements environment |

Reinforced Fiberglass

In order to ensure the mechanics and durability of the grating, Shirui uses only high quality non-alkali glass fiber.

| Specification | Category | Characteristic | Applications |

|---|---|---|---|

| E-2400TEX | Alkali-free roving (E glass) | Excellent infiltration performance, firmly bonded with the resin matrix, so that the grating has excellent mechanical properties and corrosion resistance | For high strength and corrosive applications |

Filler

| Filler type | Performance | Applications |

|---|---|---|

| Aluminum hydroxide | Flame retardant, reinforced, oxygen index 28 or above | Flame retardant, smoke suppressing environment |

| Calcium carbonate | Reinforced, proper cost reduction | No fire retardant request |

| No filler, pure resin | Good transparency, corrosion resistance | No fire retardant request, high corrosion application |

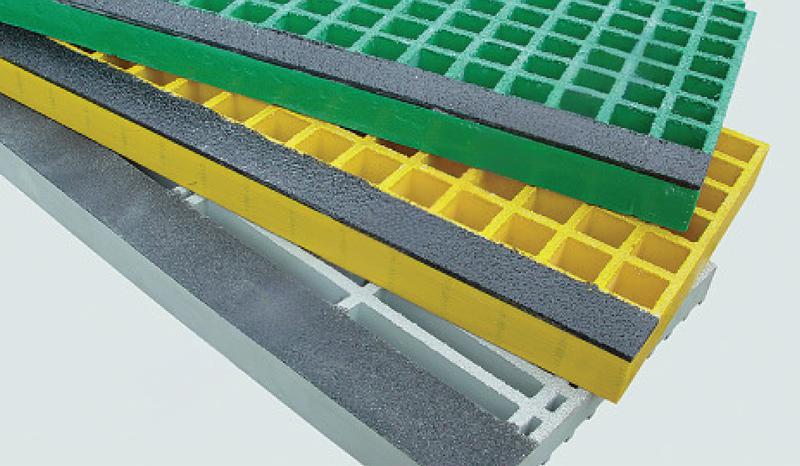

Natural Concave Surface

The naturally formed crescent grooves(concave surface) give it good anti-slip properties.

Gritted Surface

The surface of the grating is gritted with quartznds, which makes the anti-slip performance even better.

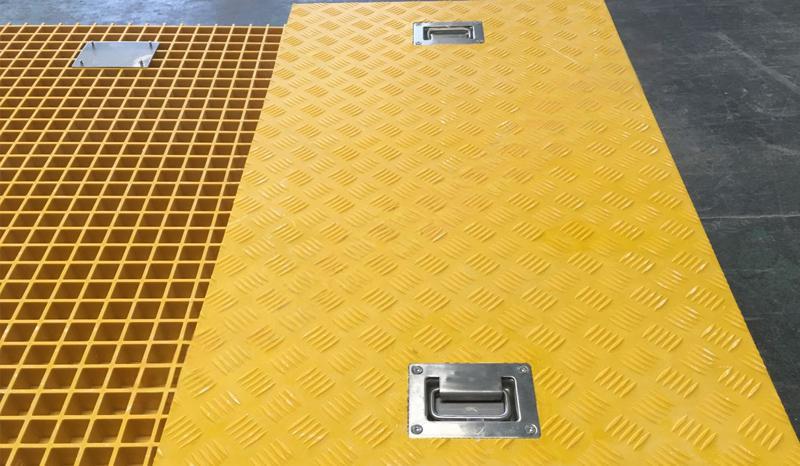

Closed Covered Surface

The surface of the grating is decorated with checker or gritted plates to prevent dripping of liquid and evaporation of gas.

Smooth Surface

Surface polishing treatment makes it more delicate and beautiful.

Stair Treads

Black sanding plate at the front end is more eye-catching and safer.

Tread Covers

Conductive Grating

Resistance≦108Ω

Transparent Gratings

Frp Covers(Type 1)

Frp Covers(Type 2)

Fabrication And Assembly

The gratings can be easily cut or perforated with a manual cutter equipped with a diamond cutter blade or even with a regular hacksaw blade, the grating can also be drilled with a driller, but not lathed or tapped.

Certainly, in order to minimize the waste during cutting, the size of the site and the size of the grating should be statistically analyzed before cutting to ensure the maximum economic benefit.

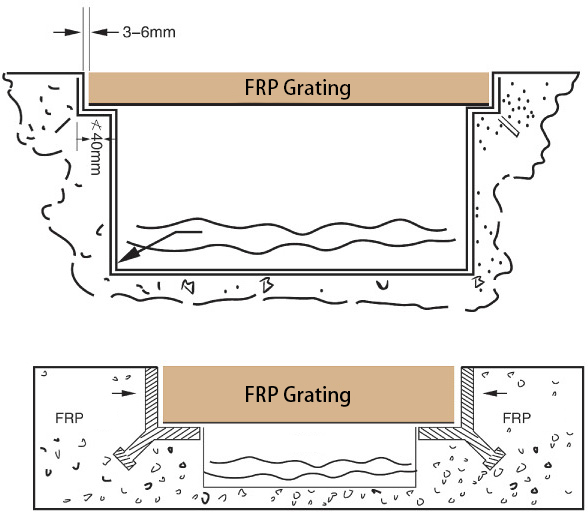

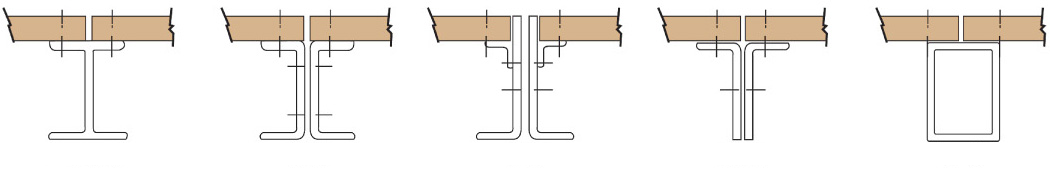

At least 40mm wide supporting is needed each side of the grating. When the grating is used as a trench cover, it can be installed without fixing fasteners because the trench is usually left with a stop, but when it is used as an operational walking platform on the structure, at least 4 sets of fixing clips are required for each grating, and the bottom of the connection between the gratings should be supported by a secondary beam.

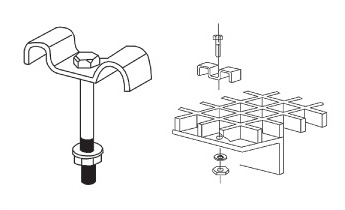

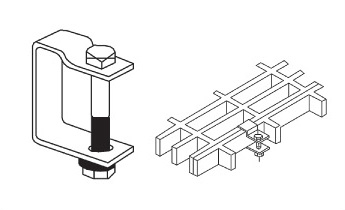

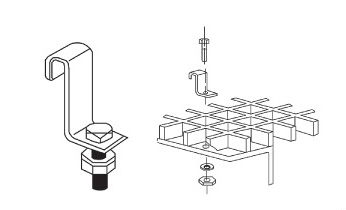

Three popular standard fixing clamps/clips are commonly used for fixing and connecting gratings to frames and gratings to gratings. All clamps are available in either stainless steel or hot-dipped galvanized versions.